15 Ways in which Industrial Internet of Things affect World Class Manufacturing 4.0

- Umeme Africa

- Sep 19, 2022

- 3 min read

Updated: Jan 16, 2024

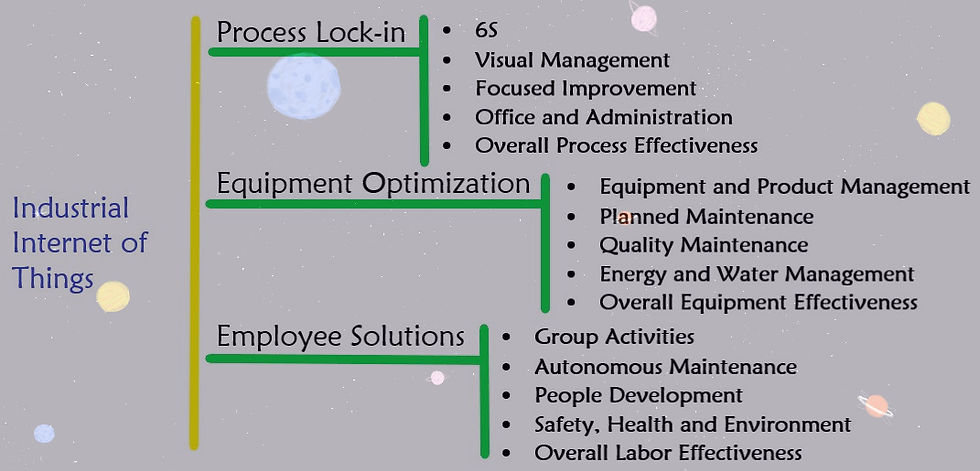

The Industrial Internet of Things (IIoT) emerges as a transformative force in the realm of manufacturing, seamlessly connecting the physical shop floor environment with the cyber world through sensors, devices, and machines endowed with sensing and actuating capabilities. This fourth industrial revolution technology brings about digitization and datafication of industrial processes, paving the way for World Class Manufacturing 4.0 (WCM 4.0). Let's explore 15 ways in which IIoT reshapes the landscape of world-class manufacturing:

1. Digitalized 6S Implementation

IIoT enhances the application of 6S (safety, sort, shine, set-in-place, standardize, sustain) through digital checklists, breaking down barriers between management and shop floor employees. Handheld devices facilitate 6S training, fostering awareness and building a comprehensive database for standards and sustainability.

2. Enhanced Visual Management

IIoT elevates the visibility of WCM structural elements by displaying real-time key performance and process indicators. Analytics from IIoT data provide dynamic visualizations, offering descriptive, diagnostic, predictive, and prescriptive insights into WCM components.

3. Optimized Focused Improvement

IIoT facilitates organized data collection and analytics, uncovering correlations between defects and root causes. By prioritizing losses related to process lock-in, people solutions, and equipment optimization, IIoT enables focused improvement initiatives with widespread sharing of information for enhanced collaboration.

4. Empowered Office and Administration

Introducing IIoT into the office and administration pillar streamlines resource usage, automates engagement platforms, and integrates employees' calendars. IIoT devices, such as cameras and wearables, contribute to data collection for payroll, maintenance tracking, and smart office assistance, improving communication and transparency.

5. Real-time Overall Process Effectiveness (OPE)

IIoT offers end-to-end real-time visibility of key performance indicators (KPIs) beyond Overall Equipment Efficiency (OEE) and Overall Leadership Effectiveness (OLE). Process metrics such as yield, cost, throughput, and employee quality output are empowered by IIoT, providing a comprehensive view of the manufacturing operations value stream.

6. Automated Equipment and Product Management

IIoT enables automation, process control, and real-time monitoring of equipment and product processing. From spares replacement analysis to product definition and development, IIoT devices enhance machine line speeds, improving product traceability and quality control metrics.

7. Proactive Planned Maintenance

IIoT facilitates real-time and unmanned equipment condition monitoring, empowering planned maintenance by predicting future breakdowns and enabling proactive solutions. Analytics provide insights into key metrics such as minimum time between failures (MTBF) for effective planned maintenance.

8. Real-time Quality Maintenance

IIoT enables real-time and proactive quality control through various sensors, eliminating human intervention in product data collection. Sensors detect and control deviations from the norm during production activities, enhancing product quality and minimizing customer dissatisfaction.

9. Smart Energy and Water Management

IIoT enables real-time monitoring of energy and water resource utilization, allowing organizations to visualize and control consumption on a dashboard. Analysis provides insights for managing resource stock levels, reducing wastage, and improving overall process efficiency.

10. Granular Overall Equipment Efficiency (OEE) Monitoring

IIoT provides real-time data on equipment availability, performance, and quality output, allowing granular monitoring of OEE. Analytics break down equipment availability, performance, and quality output into various components, offering a detailed view for optimization.

11. Empowered Group Activities

IIoT encourages employees to take ownership of processes through digital platforms, minimizing human errors in data input. Analytics offer visualization and analysis of individual and group performance, bridging the communication gap between managers and shop floor workers.

12. Improved Autonomous Maintenance (AM)

IIoT significantly enhances AM by transferring maintenance activities from operators to devices. This shift allows operators to focus on critical processes while IIoT devices handle tasks like cleaning, oiling, and inspections, improving equipment ownership and employee engagement.

13. Revolutionized People Development

IIoT enables real-time access to information, reviews, and feedback for employee training. Analytics customize and boost employee training, introducing unbiased evaluation systems for performance and fostering leadership development through mentor-mentee matching.

14. Safety, Health, and Environment Monitoring

IIoT devices provide access points to enterprise networks, measuring air quality, radiation, and environmental hazards. IIoT's additional security layer protects against unauthorized use, ensuring the safety and well-being of employees.

15. Monitored Overall Leadership Effectiveness (OLE)

IIoT aids in monitoring OLE by considering employee availability, performance, and quality of work. Telepresence technology reveals employee work patterns, providing insights on how to improve engagement, productivity, and overall leadership effectiveness. IIoT analytics pave the way for data-driven decisions to enhance employee output

Comments