Cloud Manufacturing environment in WCM 4.0

- Umeme Africa

- Sep 11, 2022

- 6 min read

Updated: Jan 15, 2024

Delving into the realm of cloud manufacturing through the lens of Joseph A. Schumpeter's innovative theory (1880) unfolds an enlightening perspective. Schumpeter's framework classifies innovations into five categories: the introduction of a new product or a novel method for an existing one, the application of innovative manufacturing methods, the exploration of new markets, the acquisition of fresh industrial tools, and the establishment or disruption of a monopoly in the manufacturing structure.

In the context of Cloud Manufacturing within the WCM 4.0 paradigm, it emerges as a fourth industrial revolution technology approach embracing a service-oriented operational model. This transformation, facilitated by cloud computing, empowers WCM 4.0 to aim for zero downtimes, accidents, waste, and breakdowns, thereby revolutionizing traditional manufacturing capabilities and resources.

Cloud Manufacturing unfolds itself through five distinct architectural types: monolithic, microservices, single-tenant, multi-tenant, and multi-instance architectures. The traditional monolithic architecture, functioning as an indivisible module, is suitable for scenarios with minimal cross-cutting concerns, simplified monitoring, and straightforward testing. However, it faces challenges in scalability, making significant changes, and overcoming technological barriers.

Contrastingly, the microservices architecture operates on a modular basis through Application Programming Interfaces (APIs), allowing independent deployment of functions. This flexibility enables the updating, upgrading, and scaling of each service separately, fostering agility in response to evolving requirements.

The single-tenant architecture is tailored for exclusive use by one manufacturer at a time. While it ensures enhanced security and customization, it comes at the cost of being resource-intensive. For manufacturers with similar operations in different regions but unwilling to share resources, a multi-single-tenant architecture provides a dedicated environment for each, optimizing security and customization but introducing complexities in integration and maintenance.

The multi-tenant architecture, focused on shared software and databases, reduces environmental and infrastructure costs. However, this efficiency brings challenges in customization, updating, and introduces potential security vulnerabilities due to shared resources.

In the multi-instance architecture, parallel execution of separate software data items eliminates resource juggling, resulting in improved performance, security, availability, and ease of scaling. Despite these advantages, the intricacies of maintenance and frequent deployment make it a costly and challenging option.

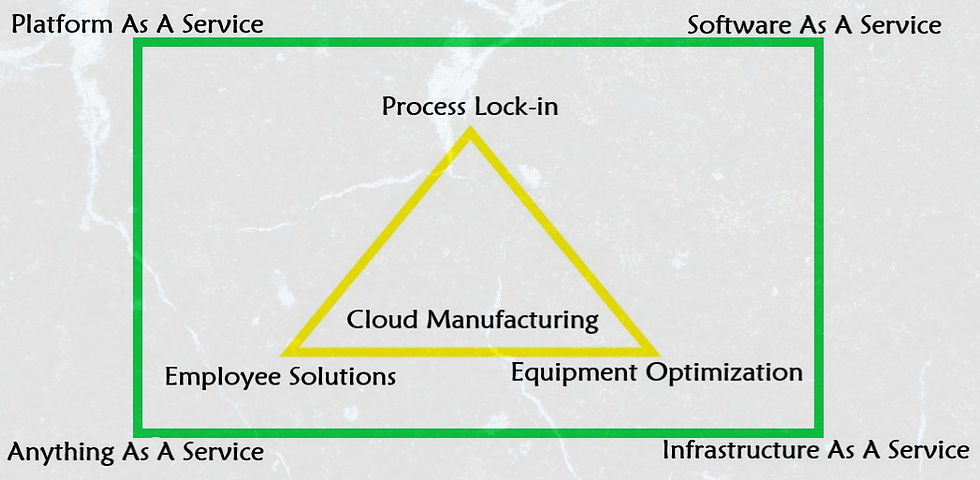

Cloud manufacturing manifests itself in four fundamental models: Infrastructure as a Service (IaaS), Software as a Service (SaaS), Platform as a Service (PaaS), and the all-encompassing Anything as a Service (XaaS). Each of these models represents a unique facet of cloud manufacturing, offering diverse solutions to meet the evolving needs of modern industries.

Infrastructure as a service

Embarking on the enlightening journey of Infrastructure as a Service (IaaS), we discover a landscape where cloud service providers extend virtual computing resources, including CPU, storage, and network components, to manufacturers. In this realm, manufacturers wield reliable control over the infrastructure, unlocking a multitude of possibilities. IaaS unfolds in seven distinctive frameworks: Nimbus, Eucalyptus, OpenNebula, OpenStack, CloudStack, AbiCloud, and Xen Cloud Platform.

Nimbus, a notable contender, aligns seamlessly with EC2 (Elastic Compute Cloud) and S3 (Simple Storage Service), offering manufacturing a trove of capabilities. EC2's relevance is underscored by its prowess in configuration, scheduling, network leasing, usage accounting, remote deployment, and life cycle management of virtual machines. Meanwhile, S3 facilitates the storage and recovery of data from anywhere over the internet through a user-friendly web service interface.

Eucalyptus, an acronym for Elastic Utility Computing Architecture for Linking Your Programs to Useful Systems, empowers organizations with the ability to pool computing resources on a single interface. This enables the calculation of available resources in private and public cloud services, playing a crucial role in integrating information in the WCM 4.0 era.

OpenNebula emerges as a powerful open-source management tool, propelling virtualized data centers towards private, public, and hybrid clouds. Its compatibility with cluster-like setups, coupled with a single frontend housing a management interface and a cluster of nodes, positions it as an ideal solution for building and managing highly distributed edge cloud environments—a pivotal component of the Industrial Internet of Things (IIOT).

OpenStack, another open-source infrastructure, empowers manufacturers to seamlessly augment their clouds with servers, storage, and networking components. This robust platform comprises vital constituents such as authentication service, image service, compute service, network service, dashboard service, block storage, and object storage, ensuring efficient cloud expansion.

CloudStack, yet another open-source gem, empowers manufacturers to provide private and hybrid cloud services on their premises. Its five components—hardware configuration, clusters, primary storage, secondary storage, and availability zones—form a comprehensive framework for virtualization tailored to diverse manufacturing needs.

AbiCloud, a beacon in open-source cloud computing infrastructure, facilitates the creation of private clouds within an organization's firewall. This proves invaluable for manufacturing entities with diverse system architectures, allowing them to scale seasonally, develop, test, pre-produce, and produce on-demand. AbiCloud's flexibility extends to instant de-provisioning when needs cease to exist.

The Xen Cloud Platform, an open-source solution for server virtualization and cloud manufacturing infrastructure, introduces the XEN hypervisor. While it may not offer a complete cloud infrastructure solution, it plays a crucial role in the realm of cloud management systems.

In unraveling the intricacies of IaaS and its frameworks, we witness the evolution of manufacturing capabilities and the transformational potential embedded in cloud computing landscapes.

Software as a service

Embarking on the captivating realm of Software as a Service (SaaS) in cloud manufacturing unveils a transformative approach where organizations, instead of owning software, subscribe to its utilization. Within this paradigm, manufacturing software resides on a cloud platform or infrastructure, sparing the manufacturer from delving into development or programming intricacies. The software is adeptly configured or customized to seamlessly integrate with the unique manufacturing environment.

In this dance of innovation, the SaaS provider takes center stage, hosting and managing the application in its data center, extending its availability to multiple organizations. The accessibility is simplified, as users navigate the software through a web browser, armed with distinctive login credentials. This not only streamlines the manufacturing process but also enhances collaboration and efficiency.

The application of the SaaS model within the WCM 4.0 landscape transcends boundaries, finding its place in diverse operations and productivity software realms. From process lock-in to people solutions and equipment optimization, SaaS becomes the guiding force, shaping a dynamic and responsive manufacturing ecosystem.

Within the manufacturing tapestry, SaaS unfurls into two intriguing models: Horizontal SaaS and Vertical SaaS. The Horizontal SaaS model casts a wide net, addressing a spectrum of manufacturing industries without bias toward the products they produce. It is a versatile approach that caters to the diverse needs of the manufacturing landscape, fostering adaptability and scalability.

In contrast, Vertical SaaS takes a targeted approach, honing in on a specific product industry. This focused model tailors its solutions to the unique challenges and intricacies of a particular sector, fostering specialized efficiency and innovation. Vertical SaaS becomes the artisan, sculpting solutions finely tuned to the nuances of a specific manufacturing niche.

As we delve into the vibrant world of SaaS in cloud manufacturing, it becomes clear that this model transcends mere software provision; it is an enabler of flexibility, collaboration, and tailored solutions. SaaS emerges not just as a tool but as a dynamic force propelling the manufacturing landscape into a new era of efficiency and adaptability.

Platform As A Service

Platform as a Service (PaaS) unfolds as a visionary cloud manufacturing model, where a third party takes the stage to host and furnish manufacturers with hardware and software tools via the internet. These tools find their purpose in application development, deployment, and operation, introducing a realm of possibilities.

PaaS, as a conductor of innovation, encompasses a diverse array of application software infrastructure, navigating through middleware landscapes. This includes integration platforms, application platforms, manufacturing analytics platforms, shop floor-streaming services, IIOT, handheld devices, and mobile back-end services. Within this rich tapestry, PaaS extends its influence beyond the technical realm, offering capabilities for process lock-in, people solutions, and equipment optimization, weaving a holistic approach to manufacturing.

Major characteristics of PaaS within the manufacturing sphere come to light, defining its impact. PaaS not only supports custom applications but also provides runtime environments, facilitating rapid deployment mechanisms. Its prowess extends to embracing a spectrum of middleware capabilities, offering services, pre-configuration capabilities, and adept API management. Security stands as a cornerstone, complemented by tools assisting developers, operational capabilities, and support for existing applications.

In the symphony of cloud manufacturing, PaaS emerges as a conductor, orchestrating a harmonious blend of technological capabilities and comprehensive solutions. It beckons manufacturers to explore, innovate, and streamline their operations, marking a transformative journey in the dynamic landscape of cloud-based manufacturing.

Anything As A Service

Embarking on the frontier of innovation, Anything as a Service (XaaS) emerges as a revolutionary network-based delivery model. In this paradigm, hardware, software, and services are not owned but are rather delivered and managed by a third party on a pay-for-use or subscription basis. Within the landscape of World-Class Manufacturing 4.0 (WCM 4.0), XaaS finds a dynamic ally in Industrial Internet of Things (IIOT) technologies, ushering in capabilities like telemetry and digital feedback.

These technological marvels play a pivotal role in WCM 4.0, transforming sensor and exogenous data into real-time operational insights. The result is a heightened transparency across processes, people, and equipment, a game-changer in the pursuit of efficiency and excellence.

In the intricate dance of WCM 4.0, XaaS takes on myriad forms, ranging from IT services encompassing safety, sort, set-in-place, shine, standardize, and sustain (6S) to group activities, visual management, focused improvement, autonomous maintenance, planned maintenance, people development, equipment and product management, quality maintenance, energy and water management, office and administration, and safety health and environment. Metrics embedded within XaaS become the compass guiding overall leadership effectiveness, overall equipment efficiency, and overall process effectiveness.

As we navigate the realm of XaaS in WCM 4.0, the possibilities are boundless. It transcends traditional boundaries, offering a holistic and adaptable approach to manufacturing, where innovation is not just a product but a dynamic force propelling processes, people, and equipment toward unprecedented heights of performance and effectiveness.

Comments