Group activities as a foundation for World Class Manufacturing

- Umeme Africa

- Mar 15, 2022

- 3 min read

Achieving significant success in manufacturing isn't a one-person journey; it's a collective effort. Enter World-class Manufacturing (WCM), a groundbreaking program that thrives on continuous improvement, aimed at achieving zero accidents, zero waste, zero breakdowns, and zero inventories. It harnesses the full potential of employees at every level and across all departments, with a singular objective: delivering high-quality products and services at competitive prices while exceeding customer expectations through flexibility and customization.

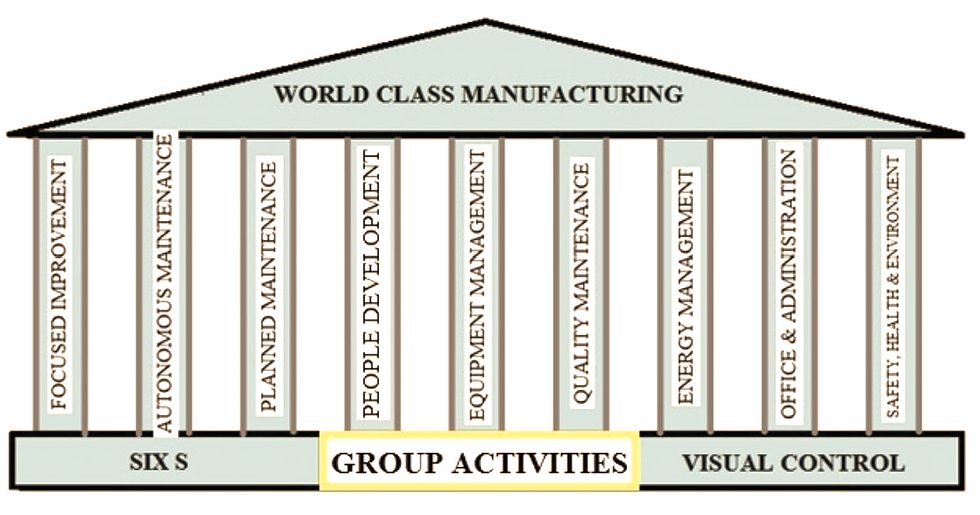

From an operational standpoint, WCM is built on several pillars that form the bedrock of manufacturing excellence. These pillars apply universally, whether you're in management or part of the labor force. They encompass focused improvement, autonomous maintenance, planned maintenance, people development, equipment management, quality maintenance, energy management, office and administration, safety, health, and environment. Group activities are the cornerstone of this WCM structure, embodying a bottom-up approach towards manufacturing excellence.

In the face of mounting challenges in the manufacturing industry, it's essential to break down interdepartmental barriers. This is where cross-functional groupings come into play, striving to enhance competitiveness and attain a leadership position in the market. Group activities lay a solid foundation for tackling the diverse challenges presented by the various WCM pillars. Each pillar, when implemented, requires the guidance of a small group, fostering coordination and cooperation among individuals. Additionally, two other foundational elements of WCM are the "Six S" approach and visual control.

The "Six S" method, comprising safety, sort, shine, set-in-place, systemize, and standardize, is a daily practice that transforms the work environment into a conducive space for productivity. Group activities under this framework reveal safety issues related to housekeeping, help identify items needing sorting, and highlight misplaced items. Furthermore, these activities aid in systemizing and standardizing housekeeping processes, optimizing overall efficiency. Visual control, within group activities, identifies areas requiring one-point lessons, making information readily available through visual cues. It also helps eliminate confusion in product and process identification by using symbols and images.

In the focused improvement pillar, group activities adhere to the Pareto principle, uncovering the crucial twenty percent of problems with the most significant impact on WCM's foundation and pillars. These activities delve deep into the root causes of issues, yielding sustainable solutions with high returns. For the autonomous maintenance pillar, group activities empower equipment operators to handle cleaning, oiling, tightening, and equipment inspections. This not only enhances equipment appearance and functionality but also heightens operator awareness of normal and abnormal equipment operation.

Groups also play a pivotal role in coordinating planned maintenance activities. By fostering a clear understanding of the organization's capabilities and resource limitations, they minimize execution flaws and ensure a seamless startup. In the people development pillar, group activities work on skill matrices needed for various processes, conduct audits, and bridge skill gaps effectively.

In equipment management, group activities regularly analyze and assess equipment performance and condition data generated by the equipment. This data not only reveals equipment deterioration but also opportunities for optimization. Quality maintenance benefits significantly from group activities as well. These activities unearth customer expectations and challenge the organization to meet or surpass them, driving product or service leadership.

Within the energy management pillar, group activities establish energy performance indicators, baselines, and carry out monitoring, measurement, analysis, and evaluation of energy performance. They also drive review and improvement efforts. The office and administration pillar oversee the documentation of WCM activities, facilitating the resources and logistics necessary for the foundation and other pillars to function optimally. This is achieved through group activities.

Lastly, group activities play a pivotal role in identifying and mitigating potential environmental hazards, accident prevention, and response planning. They develop and maintain processes and procedures that ensure zero accidents and zero environmental pollution, aligning with the safety, health, and environmental pillar.

WCM's pillars rest firmly on group activities, which complement the program's other foundational elements. While the lion may be the king of the jungle, it's the coordinated activities within the pride that make it one of the most successful hunters. In a similar vein, collaboration and synergy within manufacturing groups underpin the success of WCM.

Comments